COOKIES ON THE YOKOHAMA ATG SITE

We use cookies on this site to enhance your user experience. By clicking any link on this page, you are giving your consent for Yokohama ATG to set cookies.

October 8, 2021 << Back to Blog

October 8, 2021

During an event at Hof ten Bosch in Huldenberg, Belgium, (organised by ILVO/Inagro, Gent University and Flemish authorities) Y-ATG impressively demonstrated soil protection with flotation tires, VF technology and an air pressure control system.

Actually, it is logical. Take a tractor that is equipped with modern Very High Flexion (VF) tires such as the Alliance Agriflex 372 VF and an air pressure control system: when that tractor is operated in the field with a tire inflation pressure as low as 0.8 bar, it will be very gentle to the soil, thus avoiding compaction. It is equally logical, however, that the same cannot be said of a tractor with VF tires that is followed by a trailer with standard technology tires operated with higher inflation pressure. The positive effects of the tractor-mounted VF tires are at risk with a single pass of the trailer – particularly when the soil is wet and hence susceptible to compaction.

Holistic approach needed

Effectively protecting the soil against compaction can only be achieved when both tractor and trailer are equipped with modern tires. That is why flotation and VF technology – along with air pressure control systems – receive growing attention. This context became clearly visible at the ILVO/Inagro demonstration event.

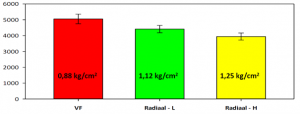

In theory, effects are obvious. That was illustrated at the event by graphs figuring the size of the tire footprint in cm2 and the resulting pressure on the soil in a comparison of VF tires (inflation pressure 1.0 bar) versus radials with an inflation pressure of 2.0 bar (“H”) and radials with reduced inflation pressure (“L”, 1.4 bar). The larger the tire footprint and the lower the inflation pressure, the lower will be the pressure exerted on the soil (fig. 1).

Fig. 1: Contact area and inflation pressure of VF and radial tires and resulting soil pressure (https://www.bodemverdichting.be/nl)

Soil pressure in kg/cm2

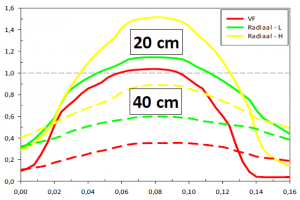

Fig. 2: Soil pressure in two depths as a result of tire type and inflation pressure (https://www.bodemverdichting.be/nl)

Soil pressure resulting from a pass with different tires and/or inflation pressures is presented in figure 2. Pressure is more pronounced in the upper soil layer (20 cm) than in the subsoil (40 cm) whilst the positive effects of VF tires and reduced inflation pressure are clearly visible in both layers. These results give evidence that – with the wheel loads tested – reduced inflation pressure and larger tire footprint result in lower soil pressure and lower soil compaction. It has to be noted, however, that higher soil moisture will reduce soil stability, thus increasing the risk of soil compaction.

These interrelations are highly important in terms of soil fertility and soil functions: Unless energy-intensive deep tillage and subsoiling are used, compaction of subsoils can cause lasting problems with regard to reduced root growth as well as restricted air and water exchange.

Yield effects

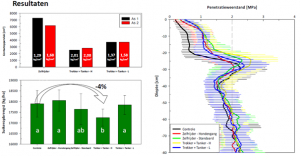

Protecting the soil against compaction is an important element of good agricultural practice for good reason: As trials within the Inagro project for example have clearly shown, soil compaction has significant impacts on yield parameters (fig. 3).

Fig. 3: Footprint and soil pressure, penetration resistance in the soil profile and resulting sugar yield in the variants control, self-propelled spreader with crab steering (AS 1), self-propelled spreader without crab steering (AS 2), tractor and trailer with high tire inflation pressure (“H”, 4.5 bar) and low tire inflation pressure (“L”, 1.4 bar), (https://www.bodemverdichting.be/nl)

Whilst there were only small yield differences between the best variants, i.e. the self-propelled spreader with crab steering and the tractor-trailer-combination with reduced inflation pressure, sugar yield was already somewhat lower in the variant with the self-propelled spreader without crab steering, and it was significantly lower following the tractor-trailer-combination operated at 4.5 bar inflation pressure. Once again, these results show that lower tire inflation pressure and larger footprint lead to lower soil compaction – and thus to lower yield losses. It could also be noted, however, that the reduced number of passes – i.e. just one pass with the self-propelled spreader with crab steering – seem to have affected soil and yield slightly less – even though without statistical relevance.

How to achieve soil protection in practice

Conserving agricultural soils as finite resource for the production of food, feed and fibre for a growing world population is of utmost importance. However, this must be achieved without compromising efficiency and productivity of farmers.

That is why engineers at Y-ATG’s Alliance brand have been continuously working on radial tractor tires, on Improved Flexion (IF) and Very High Flexion (VF) tractor tires, on radial flotation tires for trailers and – as a true world’s first – the combination of flotation and VF technology in the Alliance 389 VF-Imp tire for trailers. This tire boosts soil protection and efficient operations to unprecedented levels.

Evidence of how the Alliance 389 VF-Imp works in the field was presented during the practical demonstrations at the ILVO/Inagro event at the Bayer ForwardFarm Hof ten Bosch in Huldenberg, Belgium, on 15th September 2021. Mounted on a trailer and combined with an air pressure control system, the Alliance 389 VF-Imp made soil protection visible and measurable.

In addition to the markedly lower inflation pressure and flotation characteristics, positive effects are ensured by the large footprint of this tire. The weight of the trailer and its load are supported on a contact area that is about 25 per cent bigger than with standard tires. In addition, this tire is characterised by a very strong carcass to carry loads at 30% lower inflation pressure – which can go down to 0.8 bar in the field – steel belts for reduced rolling resistance and minimum downtime, and special compounds for better overall performance and low wear.

“As could be seen in the course of the practical demonstrations at Hof ten Bosch, flotation and VF technology offer a convincing overall package – and this even more so with an air pressure control system, allowing for a change towards a lower inflation pressure for in-field and to increase again for road transport. Of course, in case no pressure control system is available, these VF tires will run at a 30% reduced inflation pressure with even higher loads compared to standard technology tires and this for in-field and on the road transport. These tires were designed to avoid soil compaction and to allow for efficient operations – and they truly deliver. Measurements in the field with a folding yardstick and a penetrometer clearly showed the positive effects of our combination of flotation and VF technology”, concludes Gerrit Vinkers, Customer Quality Improvement and Application Specialist at Y-ATG.

Click here for an impression of Prevention Against Soil Compaction in Huldenberg.

01-Dec-2023

30-Oct-2023

16-Oct-2023

10-Oct-2023

04-Oct-2023

01-Sep-2023